0. Advantage of using 3BM retainer ring.

3BM Retainer Ring outperforms PPS in four categories.

|

No |

Items |

3BM |

PPS |

|

1 |

Abrasion resistance |

high |

low |

|

2 |

Scratch amount |

less |

much |

|

3 |

Environmental impact |

low |

high |

|

4 |

Cost(material) |

less |

much |

- PAD wear performance is more than 3 times higher.

- Scratches caused by slurry agglomeration have been reduced to less than 1/4 in the oxide film process and about half in the W process.

- Used 3BM retainer rings can be collected free of charge upon request. They are PET plastic and can be recycled.

- In terms of material-based cost, 3BM is approximately one-ninth the cost of PPS.

1. Overview

3BM®︎ resin is a material optimized for Chemical Mechanical Planarization(CMP) based on PET (polyethylene terephthalate). The pad wear resistance is approximately three times higher than that of PPS Retainer Ring. It greatly reduces the replacement frequency and contributes to the improvement of productivity. It also offers an unprecedented level of "ultra-cleanliness" in the manufacturing process so that it can be used in cutting-edge CMP processes.

2. Introduction of 3BM®︎ retainer ring

Retainer Ring is not recycled because the material is mainly PPS, which is a super engineering plastic, however our new product 3BM®︎ Retainer Ring is made with PET which could be recycled.

Retainer Ring is consumables which are being polished alongside with semiconductor wafer. It will be replaced with a new one after a few millimeters of polishing. According to our research, 500 tonnes per year of PPS Retainer Ring is disposed by landfills around the world. Replacing PPS resin with PET resin, the recycling rate can be increased from 0% to 88%.

We are aware that there are other sources of environmental damages inherent in the semiconductor manufacturing industry.

We are unable to solve all these problems, but will endeavor to be as environmentally friendly as possible.

3.Basic structure of PET material

PET polycyclic aromatic properties with the molecular chain becomes linear and easily oriented, so the degree of crystallinity is high. Thus, it has a high melting point, low water absorption and low coefficient of thermal expansion. These mechanical properties make excellent dimensional stability. It also has other properties such as electrical properties, chemical resistance, and weather resistance, which is widely used as an engineering plastic.However, due to its unique crystallization characteristics, the drawbacks are in terms of impact and heat resistance.

PET polycyclic aromatic properties with the molecular chain becomes linear and easily oriented, so the degree of crystallinity is high. Thus, it has a high melting point, low water absorption and low coefficient of thermal expansion. These mechanical properties make excellent dimensional stability. It also has other properties such as electrical properties, chemical resistance, and weather resistance, which is widely used as an engineering plastic.However, due to its unique crystallization characteristics, the drawbacks are in terms of impact and heat resistance.

4. Characteristics of 3BM®︎

3BM®︎ overcomes these weaknesses of conventional PET as it is developed solely for CMP Retainer Ring. So, it greatly reduced the occurrence of scratches.

Excellent wear resistance

Approximately 3 times of PPS → See 2) Wear resistance tests

High dimensional stability

Low water absorption and coefficient of linear expansion, with little distortion.

High strength and rigidity

It is suitable for precision machine parts because it can withstand high loads and wear.

Does not elute impurities

Chemical stability and ingenuity in manufacturing method → Refer to 4 Cleanliness Meets US FDA standards (food safety).

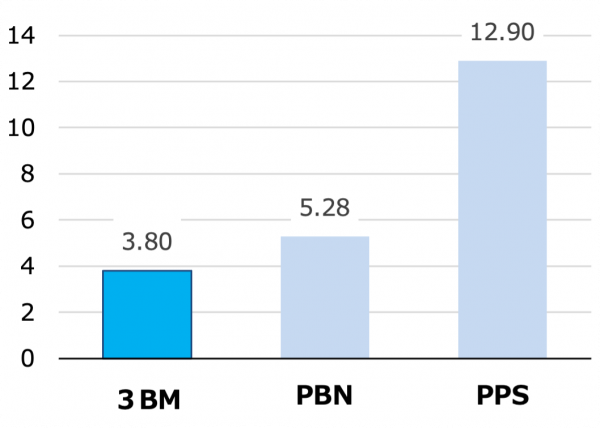

Abrasion resistance test results

|

Sample : 3BM®︎/PBN/PPS 10pieces Measurement frequency : 1hour×5times (Total measurement period 5 hours) Amount of wear : Calculate the average value for 5 hours for each sample. Amount of wear(Y) : mg/h

CMP Experimental Machine : BC-15 Sample:25mm(diameter) Slurry :Cabot SS25 Pad:Nitta Hass IC 1400 Wafer press:17psi Polish time:1hr Slurry flow rate:200ml/min |

3BM®︎ shows the least amount of wear among the three. Compared to commonly used PPS, it is about one-third or less. The PAD wear resistance of 3BM®︎ is more than 3 times than that of PPS.

Key physical properties of 3BM®︎

| Test items |

Value(Method, Unit)

|

|

Physical Properties

|

|

|

Specific Weight

|

1.39 (ASTM D792, g/cc)

|

|

Water absorption (24h in water)

|

0.07(ASTM D570, %)

|

|

Water absorption rate(Water saturation Value)

|

0.5(ASTM D570, %)

|

|

Gas emission(Mass loss ratio)

|

0.15(ASTM E595, %)

|

|

Mechanical Properties

|

|

|

Hardness (Rockwell M)

|

93(ASTM D785)

|

|

Tensile strength

|

84(ASTM D638, MPa)

|

|

Tensile elongation at break

|

20(ASTM D638, %)

|

|

Tensile Modulus

|

3.45(ASTM D638, Gpa)

|

|

Flexural yield strength

|

96.5(ASTM D790, Mpa)

|

|

Flexural Modulus

|

2.48(ASTM D790, Gpa)

|

|

Compressive strength

|

97(ASTM D695, Mpa)

|

|

Compression Modulus of Elasticity

|

2.76(ASTM D695, Gpa)

|

|

Shear strength

|

58.6(ASTM D732, Mpa)

|

|

Impact strength (Izod) NOTCHED

|

0.21(ASTM D256, J/cm)

|

|

Coefficient of friction

|

0.19(QTM 55007)

|

|

Wear Resistance

|

70.5(QTM 55010, ×0.001/N-M)

|

|

Critical Pressure Velocity

|

0.210(QTM 55010, MPa-m/sec)

|

|

Electrical Properties

|

|

|

Surface Resistivity

|

>=1.00e+13(ASTM D257, Ω)

|

|

Volume resistivity

|

>1e+14(ASTM D257, Ω・m)

|

|

Dielectric constant

|

3.2(EOS/ESD S11.11)

|

|

Dielectric tangent

|

0.02(ASTM D150)

|

|

Thermal Properties

|

|

|

Thermal conductivity

|

0.274(W/m-K)

|

|

Melting point

|

252(ASTM D3418, ℃)

|

|

Continuous maximum operating temperature (in air)

|

98.9(℃)

|

|

Deflection temperature under load (1.82 MPa)

|

98(ASTM D648, ℃)

|

|

Flammability

|

UL94(HB)

|

5. Cleanliness of 3BM®︎

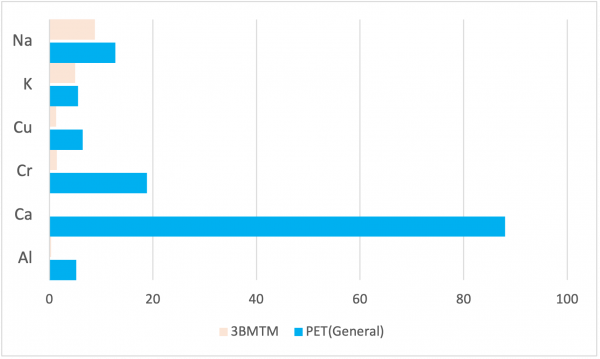

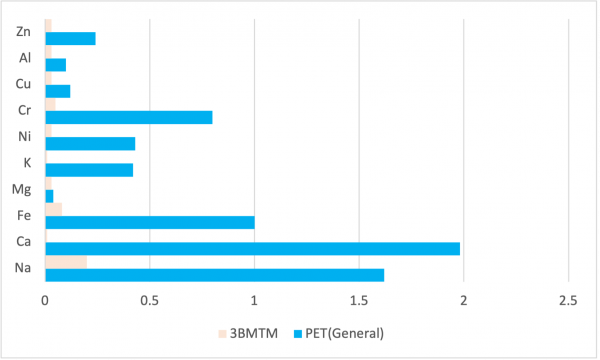

In the most advanced CMP process, scratches, and metal ions, which were overlooked in the past, are factors that reduce the yield. So, during the 3BM®︎ manufacturing process, we have achieved an unprecedented level of "ultra-clean". 3BM®︎ and normal PET were analyzed and the results were compared.

|

|

|

1) Comparison of metal contents between 3BM®︎ and general PET products ICP-OES (Inductively coupled plasma optical emission spectrometry) (Unit:ppm) |

2) Comparison of metal ion elution amount between 3BM®︎ and general PET ICP-MS(Inductively coupled plasma atomic emission spectroscopy) (Unit:ppb) As samples, 30 g each of general PET and 3BM®︎ were immersed in 5% nitric acid solution at 70°C for 4 hours. Results of measurement of eluted metal ion content. |

*The concentration unit ppb is 1/1000 of ppm.

6. Precautions for installing 3BM®︎

3BM®︎ CMP Retainer Ring is basically able to be used with the same recipe of PPS.However, when doing break-in (pre-polishing) with PPS R/Ring,

"High abrasion resistance" = "Break-in (pre-polishing)" takes more time.

If the PPS R/Ring break-in time is 30 minutes, the 3BM®︎ CMP Retainer Ring will take 3 times to do the break-in.

To solve this problem, 3BM®︎ Retainer Ring provides the pad contact surface with mirror polishing.

We will propose this mirror polishing according to the customer's CMP recipe. Wear resistance against side attack is about 1.5 times compared with PPS. This is not a significant improvement over the PPS material.

The compressive modulus of elasticity is about 5% lower than that of PPS, and the polishing rate of the wafer periphery tends to be higher than that of PPS.

There is no problem with the SUS+ type of AMAT, but in the case of the EBARA G3 type, it is around 15%. Other types such as G2S and GX shows a change of around 10%.

Selected for the Kanto Block of the Start Pitch sponsored by Nihon Keizai Shimbun, Inc.

3BM®︎ Retainer Ring's business was selected for the Kanto round of the 4th Start Pitch, a business pitch event sponsored by Nihon Keizai Shimbun, Inc.

hhttps://staatpitch.nikkei.co.jp/archives/04/list.php?blockId=b03

About sales

We offer sale of 3BM®︎ Retainer Ring and its materials. The materials are

- 8” (φ250*φ198*t20)

- 12”(φ355*φ295*t20)

If you have any questions, please feel free to contact us. (info(@)e-taise.co.jp)

*Please remove ( ) from this email address before submitting.