For those pursuing cutting-edge technology in R&D.

To all research and development professionals dedicated to pursuing the forefront of technology. We like to offer this high-quality electronic component to help you create innovative products and services, contribute to the world, and find pride and satisfaction in your work.

Imagine such a future.

You, who are pursuing cutting-edge technology in prototyping and research and development, have a high-quality, low-cost electronic component at your fingertips. You contribute to the world by creating innovative products and services with the component and find pride and satisfaction in your works.

This is not a dream.

With our ultra-compact vacuum high-power reflow furnace, this future can be realized.

Our ultra-compact vacuum high-power reflow furnace (TR-125VH3) will make your dreams come true.

Taisei Company Ltd., has built a reputation and trust as a specialized manufacturer of semiconductor and electronic component manufacturing equipment for over 40 years. We are always striving for technological innovation to meet the needs of our customers. As a result, we have developed the world's smallest ultra-compact vacuum high-power reflow furnace.

The ultra-compact vacuum high-power reflow furnace is a device used for soldering electronic components in a vacuum or nitrogen atmosphere. Compared to traditional reflow furnaces, it offers following advantages:

- 3 times faster heating speed (21°C/min).※Our company comparison

- Improvement in cooling performance when combined with a cooling reflow plate (achieving a difference of 65°C or more from natural cooling).

- Prevention of oxidation in a vacuum environment, allowing for high-quality soldering.

- Ability to heat at low temperatures, preventing component degradation or distortion.

- Elimination of the need for cleaning agents, reducing costs and environmental impact.

- Output of temperature profiles to a PC is possible when used with a dedicated thermal controller.

- Its ultra-compact size allows for flexible installation and transportation with less constraints.

Conventionally, vacuum reflow furnaces are often large and expensive, making them unsuitable for prototyping and R&D. Hence, we have developed the world's smallest ultra-compact vacuum high-power reflow furnace.

Key features of the TR-125VH3 Ultra-Compact Vacuum High-Power Reflow Furnace include:

■ World's smallest class: Less than 1/20 the size of conventional vacuum reflow furnaces.

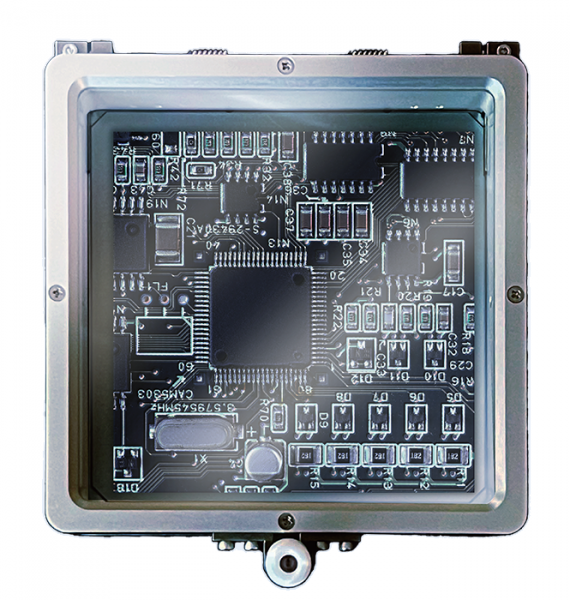

■ Good visibility: Allows for observing the state of the substrate through the window glass.

■ Low cost: Less than 1/10 the cost of conventional vacuum reflow furnaces.

■ Ease of operations: Simple operation with joysticks ,dials and buttons.

■ Atmosphere: Capable of vacuum and nitrogen purging.

■ Maximum operating temperature:300°C(constant at 260°C)

■ Heating speed: 3 times faster (21°C/min) compared to our competitors. ※Our company comparison

■ Temperature control: Ability to set temperature profiles (PC output possible when combined with a temperature controller*)

*Temperature controller sold separately.

You can check the progress through the window glass.

You can check the progress through the window glass.

In this way, the ultra-compact vacuum high-power reflow furnace(TR-125VH3) is the ideal equipment for prototyping and R&D. This product stands out compared to other products on the market. So, why can we offer such a high-performance product at a low cost? The reason is that we handle everything in-house, from development and manufacturing to sales. We develop our products based directly on the feedback and requirements from our customers. By managing production consistently in our own cooperative factories and delivering directly to our customers through our in-house sales team, we eliminate middle margins and unnecessary costs. This allows us to provide our customers with the most suitable products at better prices. We can confidently recommend the ultra-compact vacuum high-power reflow furnace (TR-125VH3) as an indispensable tool for improving your R&D and accelerating your development speed. We aim to support our customers' technological innovations with our innovative products.

Reflow Furnace Specifications Table

| TRF Series | |||||||||

|---|---|---|---|---|---|---|---|---|---|

|

furnace main unit only |

Model Number | Standard | Vacuum | ||||||

| TRF-95 | TRF-125 | TRF-125V | |||||||

|

|

|

|||||||

| Dimensions(mm) | W110×D127×H27 | W140×D157×H27 | W145×D153×H32 | ||||||

| Internal dimensions(mm) | W95×D95×H15 | W125×D125×H15 | W116×D116×H16 | ||||||

| Weight | less than 350g | less than 350g | less than 350g | ||||||

| Lid operation method |

spring-loaded opening/closing system |

Arm fixed Angle:35°、45°、55° |

|||||||

| Material | Body: Aluminum, Handle: Teflon, Window: Heat-resistant glass | ||||||||

*1 Temperature controller(Dimensions:W85×D170×H103mm Weight:0.9kg) is excluded.

*2 The equipment can be exported internationally, the nitrogen cylinder cartridges are for domestic use within Japan only. If N2 piping equipment is available, the same configuration can be applied.

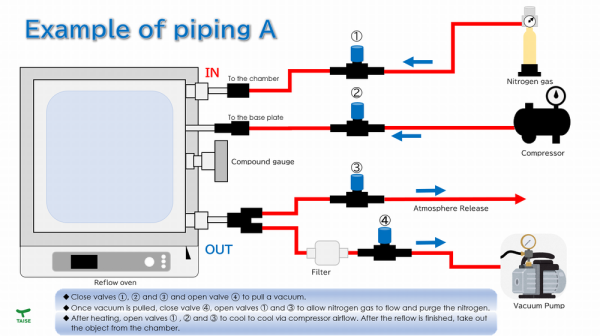

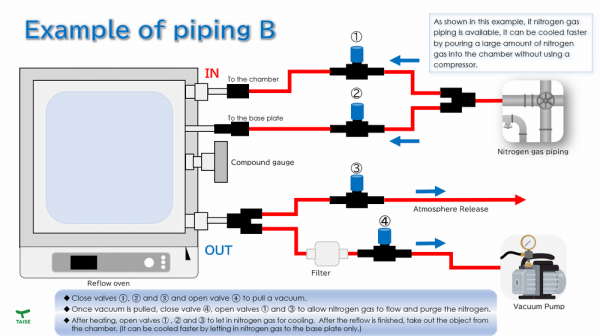

♦Reflow Furnace piping utilization examples.

Example of piping [PDF形式/330.18KB]

In-house reflow can significantly reduce time, accelerating development speed. It also helps cut costs, contributing to higher profit margins. For those currently outsourcing reflow or those who have given up due to lack of space to install reflow equipment, why not consider introducing our ultra-compact vacuum high-power reflow furnace? We look forward to receiving your inquiries and quote requests.

For those new to reflow or those who already own a reflow furnace but are interested in smaller models, please feel free to contact us. (info(@)e-taise.co.jp)

*Please remove ( ) from this email address before submitting.

We will respond to inquiries via email. Please note that the reply may take several days depending on the subject to the inquiry details.